-

Address Minsk, Dolgobrodskaya str. 16

-

Phone +375 (17) 369-18-40

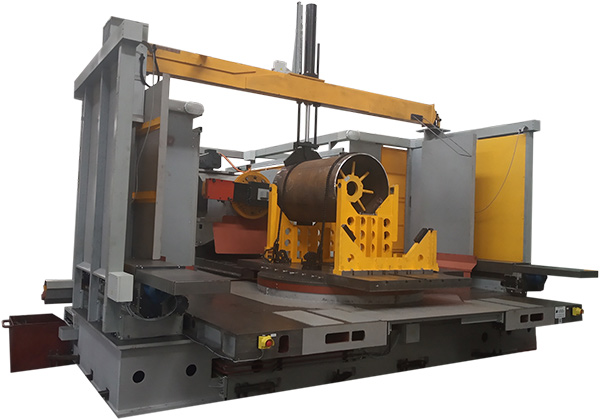

Special machine SM2484F3

Description

The machine model CM2484F3 is designed for machining tees with a diameter of up to 1420mm.

The design feature of the machine is the presence of a rotary table, which provides the possibility of processing a whole range of taps from one installation. The turntable allows parts to be rotated by 90о, 120o, 135o, 150o, 180o, 270o and 360o. The clamping of the part is provided by a moving clamp, so that the clamping is carried out close to the cutting zone, thereby eliminating the possible occurrence of vibrations.

Distinctive features of the machine are:

- High machining accuracy ensured by the presence of linear guides in the force table and faceplate, as well as the presence of a Siemens numerical control system.

- High quality of machined surfaces due to the use of the turning method and increased rigidity of the machine.

- Flexibility and ease of changeover in obtaining any chamfer profile.

- Minimum cost and quick changeover when switching to the processing of new chamfers.

- Possibility of removing the internal seam on straight sections of bends.

- Reliability and durability in work. Ability to work in 3 shifts seven days a week.

- Possibility of boring to the end with a wall thickness of up to 15mm.

Technical specifications:

Workpiece

curved bend, curved bend, reducers, tee, coils

Operations in progress

Turning, boring, cutting

Number of spindles

1 thing.

Number of positions

2(workers) things.

Number of workpieces per cycle

1 thing.

Service life before the first overhaul

12 years

Resource for accuracy to the first medium repair

11 thousand hours

Technical utilization factor

0.92 kti

Total utilization factor (design)

0,8 Ко

Loading - unloading method

Manually, by means of the Customer

Workpiece clamp

hydroficated mechanized

Chip cleaning method

manually by customer's lifting equipment

Number of electric motors

12 things.

Installed capacity

63.09 kW

Control system

f. «SIEMENS»

Noise characteristics do not exceed

80 dBA

Weight

68700 kg

Length

13930 mm

Width

11220 mm

Height

4685 mm