-

Address Minsk, Dolgobrodskaya str. 16

-

Phone +375 (17) 369-18-40

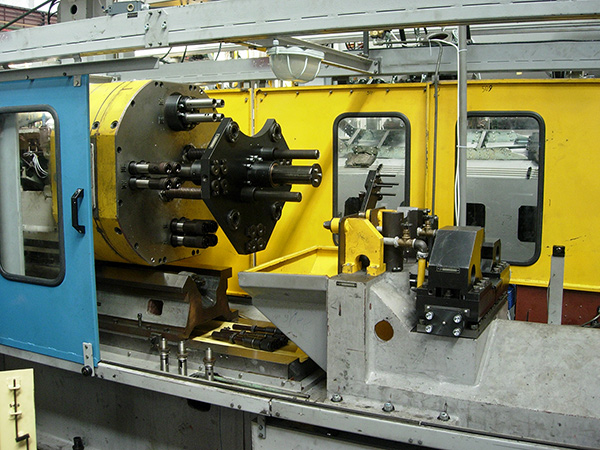

Aggregate machine AM19236.A6

Description

Special modular machine mod. AM19236 is designed for processing end holes in wagon axles. Operations performed: drilling holes, countersinking, countersinking, threading.

In the machine at one working position, 4-position turrets with rotary multi-spindle boxes with a driven tool at the working position are used as spindle assemblies, which, in addition to reducing material consumption and energy consumption, leads to an increase in the accuracy of the thread being cut. The machine has flexibility and the smallest possible dimensions, it can be built into an automatic line.

Technical specifications:

Workpiece

axis RU1SH

Operations in progress

drilling, countersinking, threading

Cycle time

6.45 min.

Number of spindles

32 pcs.

Number of positions, turrets

4 pcs.

Number of workpieces per cycle

1 pcs.

Nominal performance (at 100% usage)

9.3 pcs / hour

Design performance

6,5 pcs / hour

Service life before the first overhaul

12 years

Resource for accuracy to the first medium repair

11 thousand hours

Technical utilization factor

0.76 kti

Total utilization factor (design)

0,7 Ко

Loading - unloading method

automated

Workpiece clamp

electrified

Chip cleaning method

mechanized

Coolant consumption

100 l/min

Number of electric motors

12 pcs.

Installed capacity

24.06 kW

Control system

SIEMENS

Noise characteristics do not exceed

80 dBA

Weight

18200 kg

Length

8 280 mm

Width

2200 mm

Height

1800 mm