-

Address Minsk, Dolgobrodskaya str. 16

-

Phone +375 (17) 369-18-40

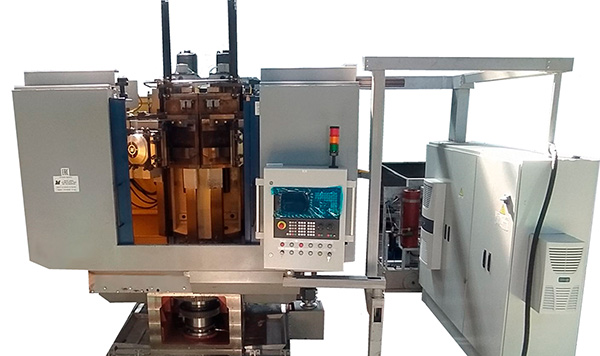

Semi-automatic turning vertical with CNC mod. 1A734F3 / 1A751F3

Description

Semi-automatic turning vertical with CNC mod. 1A734F3 / 1A751F3 are designed for:

- rough and finish turning in the chuck of the outer and inner surfaces of parts with rectilinear and curvilinear generatrices (such as discs, hubs, cups, flanges, gears, flywheels, etc.) in several passes;

- turning external and internal threads, spirals at the end.

The design of the machines is characterized vertical spindle products with the following advantages:

- clearly accessible and clear working area, ergonomically favorable for manual loading and tool change;

- simple clamping of the workpiece as it rests on the base surfaces due to its own weight;

- no deflection of the work spindle due to its own weight, the weight of the workpiece and the chuck;

- convenient loading and unloading of heavy workpieces with the help of small-scale workshop tools due to the calipers set at 120 ° horizontally and the absence of fencing elements above the chuck with the doors open;

- small footprint;

- Low installation costs as no special foundation is required.

HIGH PRECISION in long-term operation is achieved due to:

- vertical spindle;

- rigid thermosymmetric machine design;

- automatic lubrication system;

- position of guides outside the chip flow zone;

- separately located heat sources – hydroelectric power stations and electrical cabinets.

HIGH PERFORMANCE ensures:

- parallel use of two freely programmable cross calipers with 4-position turrets and highly dynamic feed drives with ball screws;

- stepless main drive from a powerful asynchronous electric motor with frequency control;

- spindle headstock with automatic switching in the cycle (according to the program) of the pre-spindle block, providing two ranges of power characteristics;

- oriented spindle stop for easy loading of asymmetric parts;

- the ability to quickly switch from processing one part to another;

- the presence of a device for setting tools outside the machine

AUTONOMY OF OPERATION is ensured by the presence of:

- own coolant system (tank, pumping station, filters);

- two 2-screw chip evacuators capable of removing a large amount of “uncomfortable” chips from the cutting zone, which are formed during the processing of ductile alloy steels;

- systems for separating coolant from chips.

Technical specifications:

Accuracy class according to GOST 8-82

П

The largest diameter of the workpiece:

- above the bed

630/560 mm.

- above the caliper

500/320 mm.

Maximum workpiece height

200/350 mm.

Maximum drilling diameter in one pass

32 mm.

Spindle end (nominal size) in accordance with GOST 12595-85

15/11

Spindle hole diameter

100 Н7 mm.

Distance from the bottom of the base of the semiautomatic device to the end of the spindle

1180 mm.

The greatest sectional height of the installed cutters

32 mm.

Spindle speed limits

10-710/14-1000 rpm

Number of automatically switched spindle speeds

stepless regulation

Number of calipers

2

The largest movement of calipers:

- in the vertical direction

600 mm.

- in the horizontal direction

330 mm.

Speed of fast movements of calipers:

- in the vertical direction

10 m/min

- in the horizontal direction

10 m/min

Speed of working feeds of calipers

1-1250 mm/min

Discreteness of task of movement of calipers:

- in the vertical direction

0,001 mm

- in the horizontal direction

0,001 mm

Number of turret positions

4+4

Number of turret tool attachment points

8…16

Main drive power

45/37 kW

Maximum cutter feed force:

- in the vertical direction

20000 Н

- in the horizontal direction

20000 Н

Maximum allowable torque on the spindle

5000 Нm

Service life before the first overhaul

14 years

Accuracy Resource

9 thousand hours

Weight

16440/13470 kg

Length

4330/4275 mm

Width

4330/4145 mm

Height

3630/3500 mm